The production department has these certificates:

- Quality management system ISO 9001

- Environmental management system ISO 14001

- Announcement about quality supplying ATEX

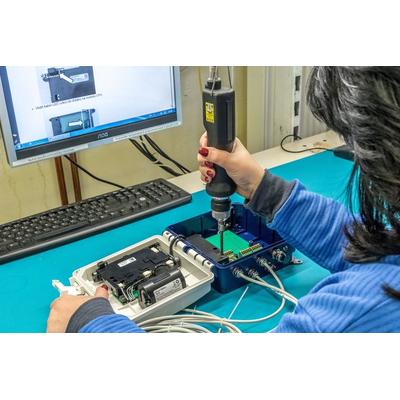

The product has to pass calibration and several controls when is finished:

- Device parametrization, temperature, and pressure calibration

- Technical control

- Metrology

- Final product inspection

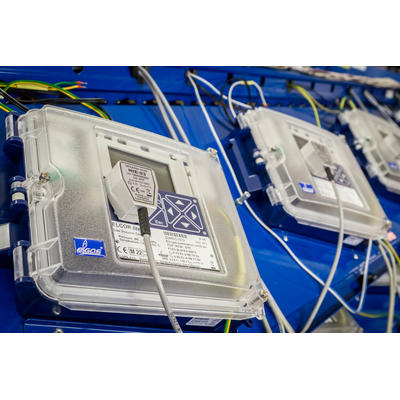

To achieve the highest possible quality and accuracy of manufactured equipment, the production line is equipped with the latest technologies and modern test equipment, which are connected to the information system. The company's own development and production process allow the company to maintain full control over the quality of its processes and outputs. The company has long modernized processes aimed at automation and robotization of production in order to achieve maximum efficiency of all production processes. The company's goal is to market such devices that are in the European concept of smart metering, smart grids and can communicate in new generation networks.

Production of gas volume conversion devices

Since its establishment in 1992, ELGAS Company has been dedicated to the development and production of correctors for telemetric commercial gas measurement. Over the years, our commitment to innovation has led to the introduction of several generations of correctors, each continually enhanced to align with the evolving technological landscape of the gas industry.

At our production facilities, we meticulously manufacture correctors, gas meters and other measuring devices, adhering to stringent requirements and quality standards. Every aspect of our equipment undergoes rigorous testing in our state-of-the-art metrology laboratories, ensuring precise values and optimal performance.

ELGAS remains steadfast in its pursuit of excellence, consistently delivering reliable solutions that meet the dynamic demands of the gas sector.